AA Composites International Pty Ltd

Unit 4, 23 Londor Close, Hemmant Q4174 Australia

Business Hours

Monday - Friday

8 a.m. - 4 p.m.

Saturday

closed

Sunday

closed

Everything you require for your composites, resin, boating and RV needs from AACI -AA Composites International - We welcome our New Zealand Friends!

Return to HOME PAGE (www.aaci.au)

(Why not ask about our VIP Membership)

View product range

Remember that when buying many items at the one time from our store, you can click on the freight discount box at the time of your checkout, and receive a freight discount (this does not apply to DG Dangerous Goods freight)

Platinum New UltraClear Epoxy Resin Kit 2:1 ratio - contains high-quality resin and hardener, formulated in Australia for Australian conditions. (Epoxy Resin Kit is supplied as a complete pack with the correct amount of hardener). The Epoxy Resin Kit is a Low Viscosity Epoxy Resin that can be used in a huge variety of applications including boat hulls and structures which need to completely exclude moisture, as well as laminating and bonding of nearly all materials. When modified with fillers such as wood powder or Colloidal Silica the resin can be used as a filling and fairing compound with outstanding results. These resins can also be used with most types of fibreglass (if using Chopped Strand Mat, you will need a special 'Powder bound' CSM for Epoxy Resin which is available from us), carbon fibre, or kevlar, as well as used over urethane foams and other sandwich core materials. These resins tend to be fairly rigid when cured.

Directions for use: Mix resin and hardener EXACTLY in the ratio shown on the label (you can use a Epoxy Resin Pump Kit to measure the correct ratio for you, but these are so problematic, as they can suck air, or can sometimes have crystals form in the pumps - ).

Coverage: It takes about 250 grams of resin to saturate a meter square of Fibreglass Cloth (200gram weight) or about 200 grams of mixed Epoxy resin to saturate 1 square meter of a flat non porous surface.

Following factors affect the curing time:

1. Mixing quantity (the more you mix, the fast it cures and vice versa).

2. Ambient Temperature (higher the air temperature will speed up the curing)

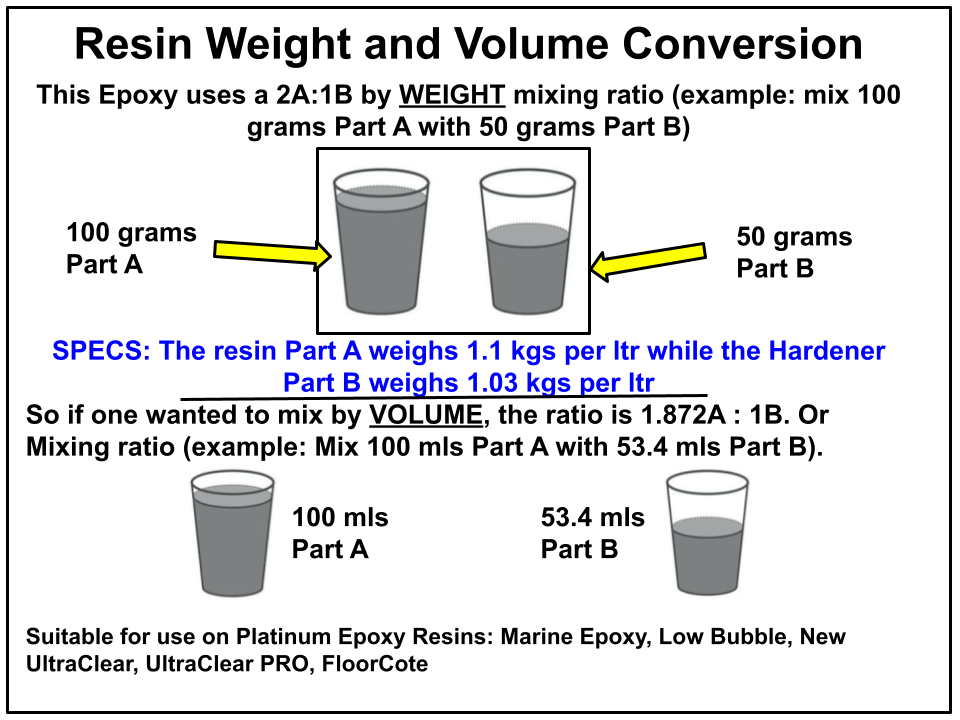

Mixing ratio: 2:1 (2 Parts A resin base and 1 Part B hardener by WEIGHT ).

Application temperature: Wide temperature range through summer to winter.

Pot life(working time): Just over 1 hour (Data based on 100ml mixing; 20 degree C room temperature).

Time to reach non-tacky: 3-18 hrs Depending on the room temperature (Data based on 100ml mixing).

Time to reach full cure: 24 hrs or more (Data based on 100ml mixing).

Viscosity: 600 cps for Part A (Brookfield 20 rpm). 150 cps for Part B (Brookfield 20 rpm).

Clarity: Pt-Co value < 10 for both Part A and Part B

Compatibility: Binding to metal, inorganic materials including cement; glass, stone, natural materials including wood; particle board, most plastics except polyethylene, polypropylene, EPDM.Shelf life of our epoxies is approx. 12 months. Product maybe supplied in alternate brand packaging but product is identical

Acetone, Cloth, Chopped Strand Mat, Fillers, Tools and safety equipment are available in our store.

Clean all brushes, rollers and fibreglass tools with Acetone.

Always wear gloves and dust masks and avoid breathing vapours of resin or dust residue.

Please Note: As this product is very pure epoxy. And it acts in a similar manner just like pure honey (epoxies act similar to honey in that, during winter honey is extremely thick and yet in summer, that same honey is very thin and runny). So it is with epoxies. And just like pure honey which sometimes turns to sugar? Pure Epoxy resin can act in a similar way and develop crystals (usually in Part A). this is not from faulty resin but common thought is that it is from the cylic hot days and cold nights when stored. An easy fix is to heat the jugs up in boiling hot water for about 30 mins and this will restore the resin to perfectly clear. The heating is also good to help remove air bubbles trapped in the epoxy due to transportation. Click this link to watch a video on crystallization

If I have to do a critical pour or application, as a tip, I heat the jugs up the day before the pour and let them cool down for the day of my pour. Additionally when mixing the two parts, I decant into the mixing container by pouring down the side of the container. All this effort is to try to limit any possible air bubbles that could ruin the finished product. Even when mixing, I use a wide rule and do not even take it off the bottom of the mixing container. Mixing is so important to get the best results and can take 3 to 5 mins.

Manufactured in Australia by Platinum Epoxies

For the material safety sheet, msg us refer SDS, do not swallow, keep away from children. CAUTION: All epoxies (except of FDA Food Grade, share the same chemical natural. Treat this like other epoxy. DO NOT SWALLOW. DO NOT CONTACT. Use all necessary PPE. KEEP AWAY FROM CHILDREN. For those with allergies? Use Platinum UltraClear Food Grade.

Disclaimer: You must be a least 21 years old to order and possess the knowledge regarding toxicity, health hazards, and all regulations required to store, use and dispose of this compound. No warranties are expressed or implied for any reason by the seller. The purchaser agrees to hold harmless the seller in any event, whether accident or injury, regarding the use or misuse of this compound. By purchasing and paying for this item, you are agreeing to this disclaimer.

May be supplied in different containers due to stock availability

Stringent production processes including testing at production and further testing at packaging are designed to prevent any possible faulty products from being sent to customers. 99.9% of customer-reported faults can be traced back to user error. We request that the customer complete a resin test before reporting a possible fault. For testing of resin, use the following link: Resin testing Additionally, when products are sold to 1000's of users worldwide without problems coming from the same source individual problems are mostly traced back to user error.

Some customers require additional information to help make their choices.

The pages being created include technical datasheets, safety data sheets, help sheets for usage, etc. and we hope that this will act as a service in helping customers gain maximum results from these stunning resins.

This product is commonly used in the pebble paving area. Mixing 1 kg of mixed Platinum New UltraClear with 20 kg of dry aggrigate is a good starting formula for pebble paving.

Package Sizes:

3kg Kit Box for transport - Total weight: 3.4kg Dimensions: 13.5cm x 21.7cm x 19.5cm

The new help pages are progressively populated. Please click on the link that follows: Technical and Help . To view SDS, click link

AA Composites International Pty Ltd - Everything that you require for your composites and resin needs!

We are based in Brisbane (Australia), and ship Australia wide as well as Internationally. Our team at AACI work closely together to get the best outcomes for our customers.

I recently purchased your Ultra Clear resin for a bench top renovation. We live in a very dated house and decided to update the kitchen, but we are on a budget.

Great resin, quick delivery. Made a new top for my dinning table that was looking old. Happy with the ocean inspired look!

Great products. Delivered to your door within the time stated. Just ordered another lot!

Business Hours

Monday - Friday

8 a.m. - 4 p.m.

Saturday

closed

Sunday

closed